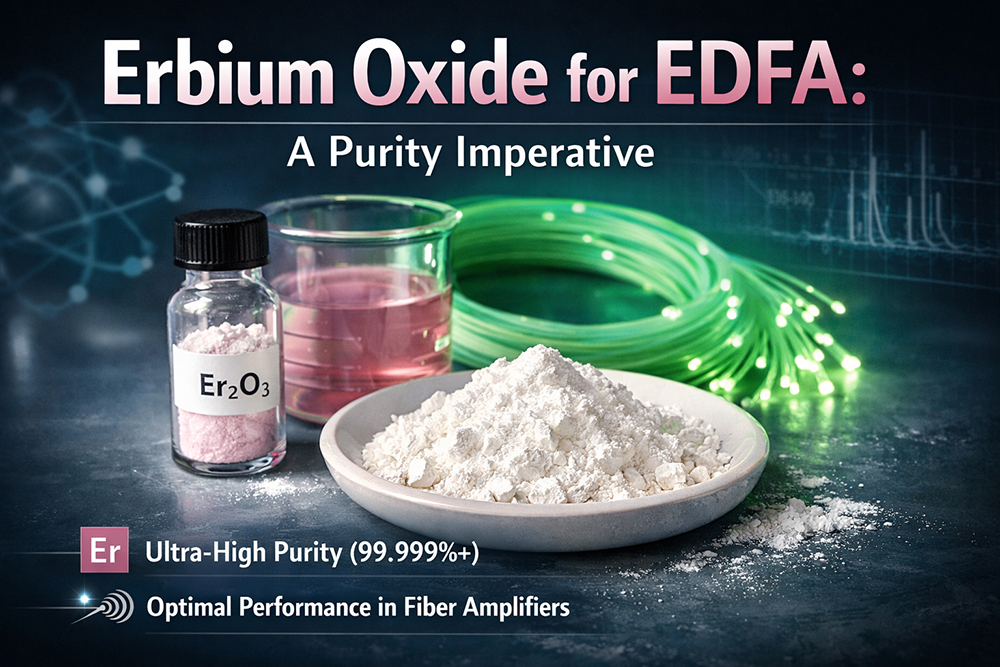

Let's be clear: the Erbium-Doped Fiber Amplifier (EDFA) is a solved problem in principle. Every textbook covers the three-level system of the Er³⁺ ion. So why do amplifier line cards from different vendors still show a measurable spread in noise figure under identical conditions? The difference rarely lies in the circuit design; it's buried in the material pedigree of the Erbium Oxide (Er2O3). For engineers and procurement specialists, this is the critical path: procuring this pink powder isn't a chemistry exercise; it's the first and most decisive step in defining your optical link's performance ceiling and total cost of ownership. Overlook the material foundation, and you're effectively optimizing the system around a compromised core.

It's tempting to view the EDFA as a commodity. It's not. It's the only viable economic engine for dense wavelength-division multiplexing (DWDM). Before its adoption, the optical-electrical-optical (OEO) conversion bottleneck made multi-channel, long-haul systems a financial and engineering quagmire. The Er³⁺ ion's singular genius is its fortuitous atomic alignment—the ⁴I₁₃/₂ → ⁴I₁₅/₂ transition—that releases energy almost exclusively within the 1530-1565nm C-band (and extendable L-band). This isn't merely "efficient"; it's a perfect match for the lowest loss window of silica fiber. This precise alignment is what transformed theoretical capacity into practical, global infrastructure.

Suppliers routinely tout "5N" or "6N" purity (referring to 99.999% or 99.9999%). The astute engineer demands the impurity ledger. The 99.999% Er2O3 is a given; it's the composition of the remaining 0.001% that governs your system's behavior. Consider the economics:

Iron (Fe) and Copper (Cu) are Signal Assassins. They don't merely attenuate light; they actively absorb the costly pump photons (at 980nm/1480nm) intended to excite Er³⁺ ions. This stolen energy converts directly into amplified spontaneous emission (ASE) noise, inflating your noise figure. It's a direct and irreversible tax on power efficiency.

OH⁻ (Hydroxyl) is a Silent Saboteur. Introduced during powder processing or preform deposition, it creates absorption peaks around 1380 nm. This increases background loss and can exacerbate gain ripple across the C-band, forcing complex and costly electronic compensation in control systems.

The Homogeneity Mandate. Even with perfect powder, inferior doping technique during the Modified Chemical Vapor Deposition (MCVD) process—the primary method for manufacturing the glass preform from which fiber is drawn—creates ion clusters. These clusters don't just quench each other's output; they become local scattering centers that induce nonlinear effects and unpredictable gain flattening.

We've moved past merely reviewing a purity percentage. The true specification is a maximum allowance per contaminant, backed by verifiable process control.

| What You're Actually Specifying | The In-Fiber Consequence | The System-Level Cost |

|---|---|---|

| Fe, Cu < 0.5 parts per million (ppm) | Eliminates parasitic absorption at pump bands. | Lower noise figure (NF), higher gain efficiency, reduced thermal load. |

| OH⁻ < 1 ppm | Prevents 1380nm "water peak" absorption. | Smoother gain spectrum, lower tilt, simpler gain-flattening. |

| Radial Dopant Uniformity | Prevents concentration quenching & modal gain variation. | Predictable gain across all channels, stable output over temperature cycles. |

The MCVD process is often depicted in clean schematics. The practical reality is a delicate dance of chemistry and thermodynamics. Introducing Er₂O₃ via solution doping requires a raw material of consistent, particle-free quality. Any deviation leads to soot layer inconsistencies in the preform. These microscopic flaws are then thermally locked in and drawn out over kilometers of fiber. The typical result isn't catastrophic failure, but a degradation of parametric yield—a wider statistical distribution of gain and noise figures across your production run. This variability is what erodes margin, not the per-gram cost of the oxide. When SMC qualifies a batch, we audit this entire integration pathway.

At Stanford Materials Corporation (SMC), our operating principle is: high-purity materials must solve problems, not become them. Our value is rooted in documented control over the variables that transform a raw material into a predictable gain medium. Our Certificates of Analysis (CoA) are, therefore, engineering documents. They don't just list impurity averages; they reveal batch-to-batch variance for critical species, providing your design team the statistical confidence to push performance boundaries without over-designing wasteful safety margins. We engage with preform manufacturers to understand specific process windows, recognizing that a material ideal for one deposition technique may be suboptimal for another.

The Bottom Line for Your Procurement Team

The lowest-cost gram of Er₂O₃ frequently becomes the most expensive component in your amplifier when assessed through the lens of wasted dB, milliwatts, and yield percentages.

Move beyond requesting a purity spec. Present your supplier with your target noise figure and gain flatness requirements. Then, request the SMC Er₂O₃ Technical Dossier and a comparative CoA to evaluate the data behind predictable performance. Let's discuss how a strategic material decision can lock in your system's competitive advantage.

Eric Loewen

Eric Loewen graduated from the University of Illinois studying applied chemistry. His educational background gives him a broad base from which to approach many topics. He has been working with topics about advanced materials for over 5 years at Stanford Materials Corporation (SMC). His main purpose in writing these articles is to provide a free, yet quality resource for readers. He welcomes feedback on typos, errors, or differences in opinion that readers come across.

Inquiry List

Inquiry List