Glass polishing takes more than just effort—it needs the right technique and the right materials. Among those, cerium oxide has become a favorite for anyone looking to bring back clarity to scratched or dull surfaces. Knowing how to use it properly—how much to mix, how to apply it, and how to avoid common slip-ups—can save you time and help you get better results.

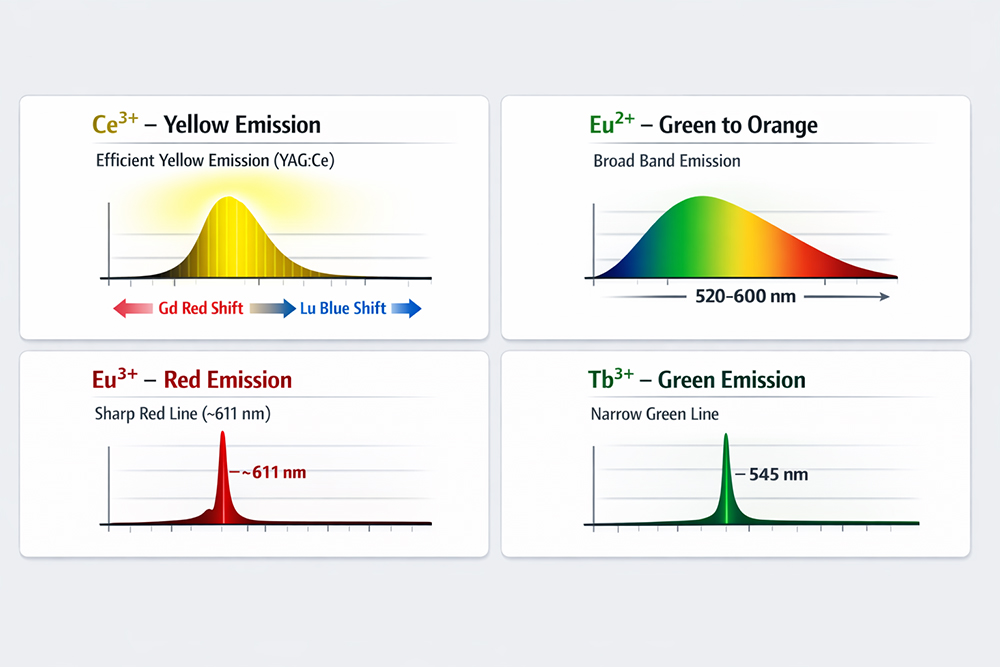

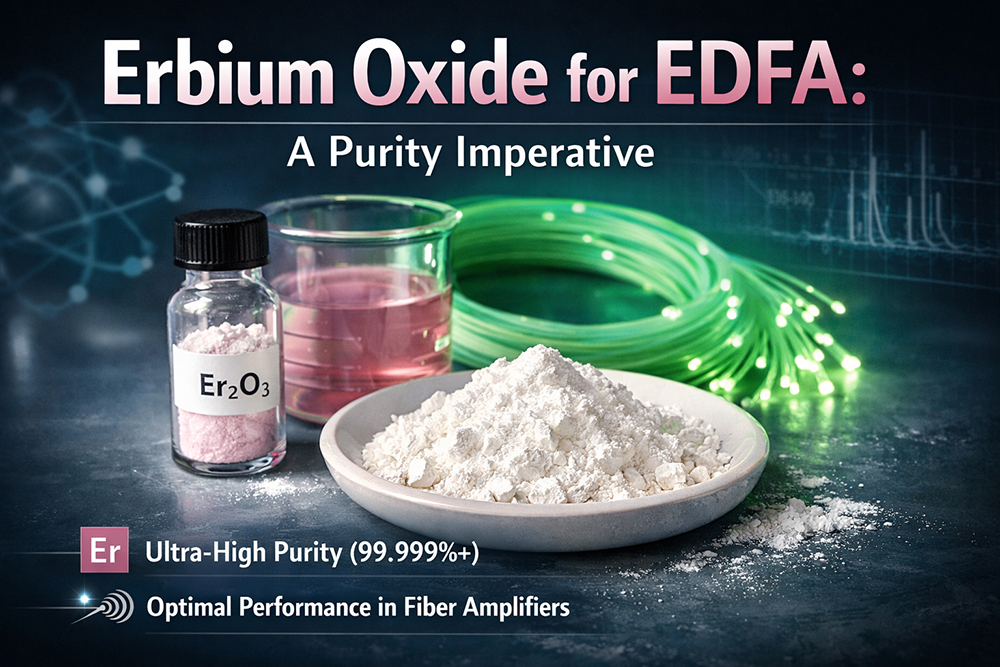

Also known as ceria, cerium oxide (CeO₂) is a soft abrasive that's great for polishing glass. It doesn’t just grind away at flaws—it smooths them out gradually, removing fine scratches without harming the surface underneath. That makes it a go-to compound for both beginners and experienced users.

The effectiveness of cerium oxide in glass polishing is closely tied to its concentration in the polishing mixture. Finding the right balance is essential for achieving optimal results. As a general guideline, a concentration of around 2-10% cerium oxide in the polishing slurry is commonly recommended. However, the exact concentration may vary based on the specific requirements of your glass polishing project.

Creating the perfect polishing conditions is crucial for maximizing the efficiency of cerium oxide. Here are key factors to consider:

Pressure: Applying consistent and moderate pressure is essential. Too much pressure can result in uneven polishing, while too little may not yield the desired results.

Speed: The speed of the polishing process is another critical factor. A moderate and consistent speed ensures that the cerium oxide has sufficient time to work its magic without causing heat build-up.

Temperature: Controlling the temperature during glass polishing is vital. Excessive heat can lead to issues such as glass warping. Ensure that the polishing process occurs at a temperature range that is suitable for the type of glass you are working on.

While cerium oxide is an excellent polishing compound, safety should always be a top priority. Here are safety measures to consider:

Protective Gear: Wear appropriate protective gear, including gloves and safety glasses, to shield yourself from direct contact with cerium oxide.

Ventilation: Ensure proper ventilation in the polishing area to prevent inhalation of cerium oxide particles.

First Aid: Have a first aid kit on hand, and familiarize yourself with the steps to take in case of accidental exposure.

Storage: Store cerium oxide in a cool, dry place away from incompatible materials, and follow the recommended storage guidelines.

Clean glass gives you a clean polish. Before doing anything else, make sure the surface is free of dust, fingerprints, or oil. Use a lint-free cloth and mild cleaner to wipe it down. If the surface isn’t clean, polishing can just trap debris and scratch it further.

Pads and tools need care, too. A dirty or worn pad will ruin your finish no matter how good the slurry is. Rinse your pads during use if needed, and don’t hesitate to replace them when they start wearing unevenly.

Don’t start on the main piece right away. If you’ve never polished that type of glass before—or even if you have—try it on a test piece first. A small trial can help you adjust the mix, pressure, or speed before it matters.

Cerium oxide can make a big difference when used with a bit of care and patience. You don’t need fancy equipment—just a decent mix, consistent technique, and a clean workspace. If you’re willing to experiment a little and adjust as you go, it’s possible to get impressive results with even a basic setup.

For a quality polishing compound you can count on, check out cerium oxide powder from Stanford Materials Corporation (SMC).

Eric Loewen

Eric Loewen graduated from the University of Illinois studying applied chemistry. His educational background gives him a broad base from which to approach many topics. He has been working with topics about advanced materials for over 5 years at Stanford Materials Corporation (SMC). His main purpose in writing these articles is to provide a free, yet quality resource for readers. He welcomes feedback on typos, errors, or differences in opinion that readers come across.

Inquiry List

Inquiry List