Cerium is the most abundant of the rare earth metals. This soft, silvery-gray metal is versatile and widely used across various industries. Its unique chemical properties make it valuable in applications such as catalytic converters, glass polishing, and alloy production. Cerium's importance continues to grow as new uses are developed.

Cerium, often iron-gray in commercial form, takes on a silvery look when pure. It is a soft and malleable metal, making it easy to work with. In air, cerium quickly oxidizes, forming cerium dioxide (CeO₂), which protects the surface from further reaction. Cerium reacts slowly with water and dissolves in most acids, except hydrofluoric acid (HF). With HF, cerium forms a stable fluoride layer that prevents further reaction.

Cerium's electronic structure allows it to shift between +3 and +4 oxidation states, adding flexibility in its chemical reactions. This unique trait supports cerium's roles in catalysis and alloying.

Cerium is one of the most common rare earth elements, found in minerals like bastnasite, monazite, and cerite. These minerals contain cerium in high enough amounts to make extraction practical. The main sources of cerium are monazite and bastnasite, which are mined in countries such as China, the United States, and Australia.

To obtain pure cerium, manufacturers use methods like metallothermic reduction, where cerium fluoride is reduced with calcium, or electrolysis of molten cerium chloride. These methods yield high-purity cerium but require precise conditions due to cerium's reactivity.

Cerium has many uses in industry due to its unique properties.

Catalytic Applications: Cerium oxide (CeO₂) is a crucial part of catalytic converters, which reduce harmful emissions from vehicles. Cerium's ability to switch between +3 and +4 oxidation states helps it break down nitrogen oxides and carbon particulates, improving air quality.

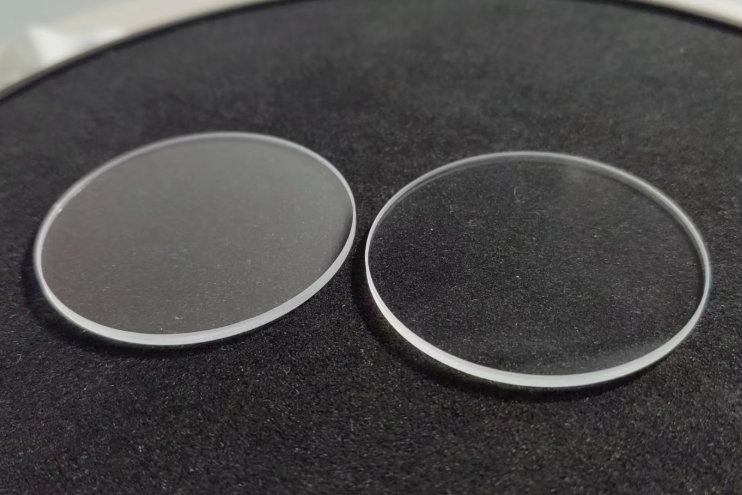

Glass and Optics Industry: Cerium oxide is also a popular glass-polishing agent. Its fine particles help polish glass surfaces to a high clarity. Additionally, cerium acts as a decolorizer, removing unwanted colors in glass products.

Alloy Production: Cerium is added to various metals, including steel and aluminum, to increase strength, corrosion resistance, and durability at high temperatures. A common use of cerium alloys is in lighter flints. Misch metal, an alloy containing around 50% cerium, produces sparks when struck, which is useful in lighters.

Chemical Analysis: Cerium compounds, especially ceric salts, serve as powerful oxidizing agents in chemical analysis. They help test for the presence of certain metals, such as iron, by reacting with them in predictable ways.

Several cerium compounds play essential roles in modern industry.

Cerium Dioxide (CeO₂): Also called ceria, this compound is widely used for polishing glass surfaces to achieve a high-quality finish. Its role as a catalyst in automotive converters makes it essential in reducing vehicle emissions. The material's ability to store and release oxygen helps break down pollutants more effectively.

Cerium Sulfide (Ce₂S₃): Cerium sulfide is used as a red pigment in plastics and coatings. It is a safer alternative to cadmium-based pigments, which are harmful to the environment. This non-toxic red pigment has gained popularity in manufacturing toys, containers, and household items.

Cerium Hydrides: Cerium can absorb hydrogen at room temperature to form cerium hydrides. This property allows it to act as a hydrogen storage material, which has potential applications in fuel cells and clean energy storage systems.

Cerium is generally safe for limited, everyday use but can pose risks in industrial settings. Workers handling cerium dust or fumes may face respiratory hazards, as prolonged exposure can affect lung function. In high amounts, cerium can also impact the liver if it accumulates in the body.

The environmental effects of cerium are mixed. Cerium compounds, especially those used in automotive catalytic converters, help reduce air pollution by breaking down vehicle emissions. However, improper disposal of cerium-containing products may lead to cerium buildup in soil and water. In aquatic systems, cerium can disrupt cell membranes in some organisms, potentially affecting their health and reproduction.

The demand for cerium and its compounds is likely to grow as new applications emerge. Cerium's role in sustainable technologies, such as fuel cells and hydrogen storage, makes it a valuable material for clean energy systems. Its use in catalytic converters and emissions control will continue to support efforts to reduce air pollution in cities. Additionally, advancements in glass polishing and pigments may lead to more efficient use of cerium compounds.

As industries seek eco-friendly materials, cerium's versatility and availability make it a promising resource for innovation in green technology.

Cerium's unique properties make it indispensable in industries ranging from automotive to optics. Its ability to catalyze reactions, polish glass, and strengthen alloys highlights its versatility. As new applications emerge, cerium's role in sustainable technologies will likely expand.

Stanford Materials Corporation (SMC) is dedicated to providing high-quality cerium and cerium-related materials to support innovation across these industries. With a commitment to quality and sustainability, SMC continues to meet the growing demand for this valuable rare earth element.

Eric Loewen

Eric Loewen graduated from the University of Illinois studying applied chemistry. His educational background gives him a broad base from which to approach many topics. He has been working with topics about advanced materials for over 5 years at Stanford Materials Corporation (SMC). His main purpose in writing these articles is to provide a free, yet quality resource for readers. He welcomes feedback on typos, errors, or differences in opinion that readers come across.

Inquiry List

Inquiry List