Yttrium oxide, also known as yttria, is a rare earth oxide with a wide range of applications in various industries. In this article, we will discuss the applications of yttrium oxide in magnetic materials, ceramic additives, phosphors, film capacitors, and special refractory materials. By examining the unique properties of yttrium oxide, we can gain insight into the important role it plays in these key industries.

Yttrium oxide is a commonly used additive in various magnetic materials, including magnetic alloys and magnetic recording media. Using yttrium oxide in these materials significantly enhances their magnetic properties, including magnetic coercivity and remanence. Moreover, as a stabilizer, yttrium oxide also improves the chemical and thermal stability of these materials.

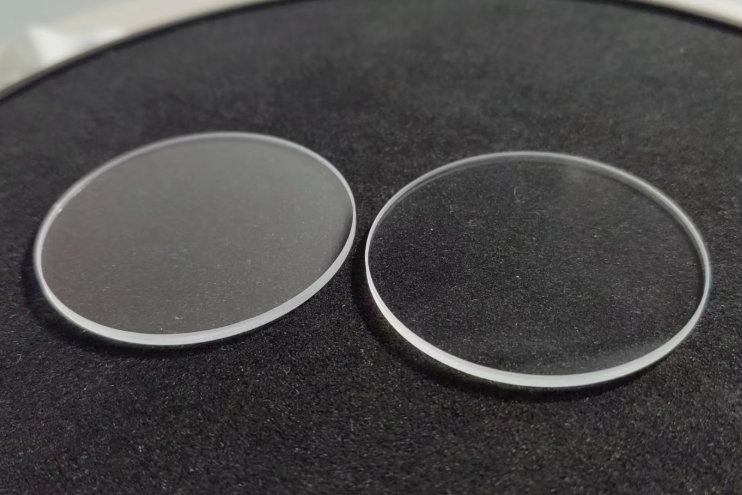

Yttrium oxide finds usage as a ceramic additive in multiple applications, such as ceramic coatings, filters, and capacitors, to enhance their mechanical properties like strength, hardness, and toughness. Additionally, it can also improve the thermal and chemical stability of ceramic materials, ultimately improving their performance and lifespan.

Yttrium oxide is commonly used as a phosphor in various applications, such as fluorescent lamps, cathode ray tubes, and plasma displays. Its implementation as a dopant in these phosphors leads to significant enhancements in luminescent properties, such as improving brightness and color purity. Additionally, when utilized as a matrix material in phosphors, yttrium oxide is known to improve both the performance and durability of the resulting product.

Yttrium oxide is widely used as a dielectric material in film capacitors which are employed in diverse electronic devices, such as smartphones, computers, and televisions. The addition of yttrium oxide to the dielectric materials enhances their insulation properties, leading to an increase in capacitance and consequently reducing the size of the capacitor. Furthermore, yttrium oxide can enhance both the thermal and chemical stability of dielectric materials, thus improving the lifespan and reliability of the corresponding capacitor.

Yttrium oxide is suitable for use in special refractory materials like high-temperature coatings, crucibles, and electrodes due to its high melting point and thermal conductivity. Yttrium oxide also improves the chemical resistance of refractory materials, increasing their lifespan and performance.

Further Reading: The Role of Yttrium Oxide in Advanced Ceramics

To sum up, yttrium oxide is a versatile material widely utilized in electronics, magnetism, ceramics, lighting, and refractory industries. Incorporating yttrium oxide into different materials can significantly enhance their mechanical, thermal, and electrical properties, leading to efficiency, lifespan, and performance improvement. As new technologies emerge, the demand for yttrium oxide is likely to increase. However, limited supply and environmental challenges associated with its extraction and processing call for sustainable and efficient production and usage methods to cater to its growing demand.

For more information about rare earth materials, please visit our homepage.

Eric Loewen

Eric Loewen graduated from the University of Illinois studying applied chemistry. His educational background gives him a broad base from which to approach many topics. He has been working with topics about advanced materials for over 5 years at Stanford Materials Corporation (SMC). His main purpose in writing these articles is to provide a free, yet quality resource for readers. He welcomes feedback on typos, errors, or differences in opinion that readers come across.

Inquiry List

Inquiry List