When we talk about dysprosium oxide, dysprosium (III) oxide, or dysprosium trioxide, we are all referring to the same material - the oxide of dysprosium (Dy2O3), a rare earth oxide. Dysprosium oxide is a slightly hygroscopic white powder that is highly insoluble and thermally stable. Its structure changes with temperature and the critical point is about 1870°C. Below this value, it has a cubic crystal structure, while it has a monoclinic and/or hexagonal crystal structure above this value.

In 1878, Per Teodor Cleve found oxides of holmium and thulium when analyzing erbium ore. In 1886, the French chemist Paul Émile Lecoq de Boisbaudran isolated dysprosium oxide from holmium oxide while studying it. He uses dysprosium oxide as raw material to try to separate pure dysprosium. He first dissolved dysprosium oxide in acid, and then employed precipitation using ammonia. After more than 30 attempts, he succeeded. He named it dysprosium after the Greek word for 'hard to get' – dysprositos.

Dysprosium oxide has many special properties, which contribute to its various applications. Its paramagnetism makes it used as a magneto-optical recording material, a large magnetostrictive material, etc.; its optical properties make it used as a fluorescent and glass material; its catalytic properties make it used as an optical and laser device dopant; its electronic properties allow it to be used in neutron spectroscopy, nuclear reaction control rods, neutron absorbers, etc. In addition to these applications, dysprosium oxide nanoparticles have recently been considered for biomedical applications such as cancer research, new drug screening, and drug delivery.

Magneto-Optic (MO) recording is a technique to write, read, erase, and store data using a laser and a magnet. Materials suitable for magneto-optical recording applications include magnetic oxides, metallic Pt-Co and Pd-Co multilayers, and magnetic alloys. Dysprosium Oxide powder is used as a magnetic oxide in magneto-optic Recording.

Luminescent materials refer to material that emits light during the process of returning from an excited state to a ground state after being excited by external energy. They are widely used in our daily life, as you can see in fluorescent lamps, plasma televisions, DVD players, etc. Most rare earth materials can be used as luminescent materials, and so can dysprosium oxide.

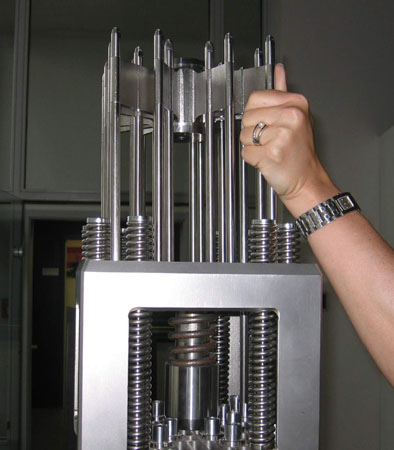

A control rod is a device used to absorb neutrons and also to control the speed of the chain reaction. Commonly used control rod materials contain chemical elements such as boron, cadmium, silver, hafnium or indium. In addition, most rare earth elements, such as dysprosium, samarium, europium, gadolinium, terbium, ytterbium, and lutetium, are excellent neutron absorbers and are also used to make control rods.

Dysprosium titanate has a high melting point, is easy to produce, does not produce radioactive substances, does not expand and does not outgas, and is a material that can potentially replace Ag-In-Cd alloys as pressurized water control rods.

Rare earth oxides have become ubiquitous materials in catalytic systems, and small additions of rare earth can provide beneficial effects to various catalytic systems. They are widely used as catalysts and also as supports for various metal-containing catalytically active phases, for example, dysprosium oxide can be used as a reinforcing agent for ceramic materials for high-temperature applications.

Dysprosium oxide is a typical representative of rare earth oxides. It has excellent paramagnetism, optical properties, electrical properties, catalytic properties, etc., so it has a wide range of applications. If you need dysprosium oxide or other rare earth materials for your project, you can visit our homepage for more information. Stanford Materials Corporation (SMC) is a worldwide supplier of various rare earth oxides, metals, alloys, advanced ceramic materials, and minerals.

Eric Loewen

Eric Loewen graduated from the University of Illinois studying applied chemistry. His educational background gives him a broad base from which to approach many topics. He has been working with topics about advanced materials for over 5 years at Stanford Materials Corporation (SMC). His main purpose in writing these articles is to provide a free, yet quality resource for readers. He welcomes feedback on typos, errors, or differences in opinion that readers come across.

Inquiry List

Inquiry List