Erbium oxide (Er2O3) is an inorganic compound consisting of erbium and oxygen, with a high melting point and exceptional resistance to harsh environmental conditions. As a rare earth oxide, it possesses unique optical and electronic properties that make it valuable in various applications. In particular, it is a versatile material in the production of specialized types of glass, given its remarkable optical properties. This property makes it essential in the manufacture of optical fibers and other advanced glass technologies, among other uses. This article provides an overview of the applications of erbium oxide in glass production, exploring its use in various types of glass and discussing some of the key benefits that this versatile material can offer.

Erbium oxide is a common dopant in the production of laser glasses. Laser glass is glass doped with rare earth elements making it suitable for use as a laser medium. The unique optical and electronic properties of erbium oxide make it particularly valuable in this application. When erbium is excited by a light source, it emits photons at a wavelength of 1540 nm, which is in the near-infrared range. This makes it useful for producing lasers that can be used in telecommunications, medical applications and other industries.

Erbium oxide is added to glass to improve its refractive index, enabling the creation of lenses and prisms. Because of this, it is important in the production of optical goods including cameras, microscopes, and telescopes. In particular, infrared filters and polarizers for various imaging and sensing applications are made using erbium-doped glass.

One notable example of the use of erbium-doped glass in optics is in the LIGO (Laser Interferometer Gravitational-Wave Observatory) project. LIGO uses a complex system of laser interferometers to detect gravitational waves, tiny ripples in space-time that are produced by cataclysmic astrophysical events such as black hole mergers. The interferometers use high-power lasers and extremely sensitive detectors to measure tiny changes in the length of the instrument's arms caused by passing gravitational waves. To achieve the required sensitivity, the interferometers use erbium-doped fiber amplifiers to boost the power of the laser beams.

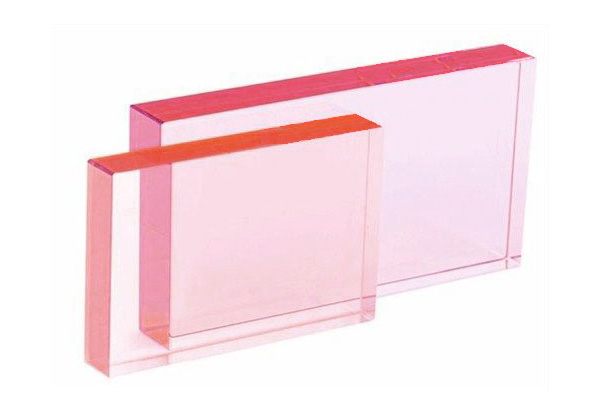

Erbium oxide is not only useful in laser glasses, but it also has applications as a colorant in glass production. It is frequently employed in the production of art glass and ornamental glassware. Erbium oxide gives a pink or rose tint that is widely valued in the industry when added to glass compositions. Erbium oxide can be used alone or in conjunction with other coloring agents to produce various colours or effects, and the strength of the pink color can change depending on the concentration utilized.

One of the most interesting aspects of erbium-doped glass is that the color can change depending on the lighting conditions. In natural daylight, the glass appears more of a pale pinkish color, while under incandescent lighting, it takes on a more vibrant and intense pink hue. The interaction between various light sources and the particular wavelengths of light released by the erbium ions is what causes this phenomenon.

The pink color provided by erbium oxide is especially beautiful when mixed with other colors, so erbium-doped glass is often used by sculptors and artists to create distinctive works of art. High-end ornamental glassware including vases, bowls, and glazed lamps are also frequently made with it.

In addition, erbium oxide has other advantages as a colorant for glass production, such as good chemical stability. It won't react with the other components of the glass, so it ensures the color remains consistent over time. It also has good thermal stability, making it suitable for high temperature glassmaking processes.

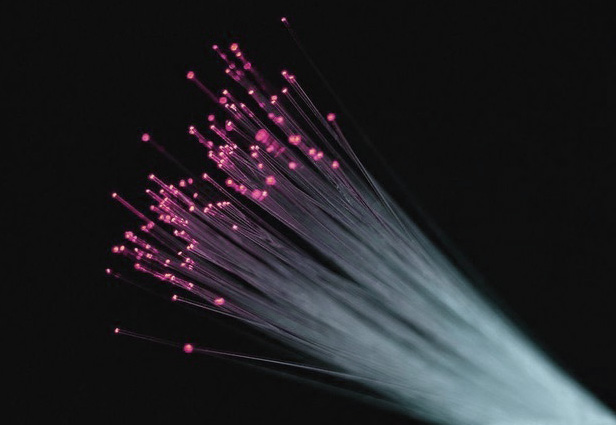

Erbium oxide is valued for its ability to improve glass' optical qualities. One important application of erbium-doped glass is in the production of optical fibers. These fibers are employed in a wide variety of applications, including data transmission and telecommunications as well as medical devices like endoscopes.

Erbium-doped fiber amplifiers (EDFAs) are used to boost the power of light signals in optical fibers in telecommunications. When light passes through an erbium-doped fiber, it stimulates the erbium ions, causing them to emit photons at a specific wavelength in the near-infrared region. This results in magnified light that can be utilized to transmit data across great distances. Erbium-doped fibers are used in communications networks to improve the efficiency of data transmission, enabling faster and more dependable communication.

Erbium-doped fibers are also used in medical equipment. Take the example of an endoscope, which is used in minimally invasive surgery, allowing doctors to see and manipulate inside the body without making large incisions. Erbium-doped fibers are also used in medical devices. Take the example of endoscopes used in minimally invasive surgery, where optical fibers pass through erbium oxide to improve the image quality produced by the device.

In addition, erbium-doped fibers also have the ability to withstand high temperatures and harsh environments, making them ideal for industrial and scientific applications.

Overall, the applications of erbium oxide in glass production are extensive and varied. Its unique optical properties make it a valuable material for the production of laser glasses, optical fibers and specialty glasses. It is also used as a stain in decorative glassware and art glass, adding a touch of beauty and elegance to such products. As the technology advances, we can expect to see more innovative uses of erbium oxide in glass production and beyond.

Stanford Materials Corporation (SMC) is a leading rare earth material manufacturer, offering high-quality erbium oxide for various glass applications. Our advanced technology and expertise allow us to produce highly pure erbium oxide with exceptional optical properties, ensuring superior performance and efficiency in the production of laser glasses, optical fibers, and specialized glass types. At SMC, we prioritize customer satisfaction by providing unparalleled technical support and customized solutions tailored to meet specific requirements. For more information about our products and services, visit our homepage or send us an inquiry directly. Trust SMC as your reliable partner in rare earth materials manufacturing.

Eric Loewen

Eric Loewen graduated from the University of Illinois studying applied chemistry. His educational background gives him a broad base from which to approach many topics. He has been working with topics about advanced materials for over 5 years at Stanford Materials Corporation (SMC). His main purpose in writing these articles is to provide a free, yet quality resource for readers. He welcomes feedback on typos, errors, or differences in opinion that readers come across.

Inquiry List

Inquiry List