Smartphones are essential in the digital era, storing memories, helping us communicate, and giving us access to the internet. With constant use, however, comes the inevitable wear and tear, most notably in the form of scratches on the screen. Such imperfections can detract from the user experience, prompting many to seek solutions for restoring their screens to pristine condition.

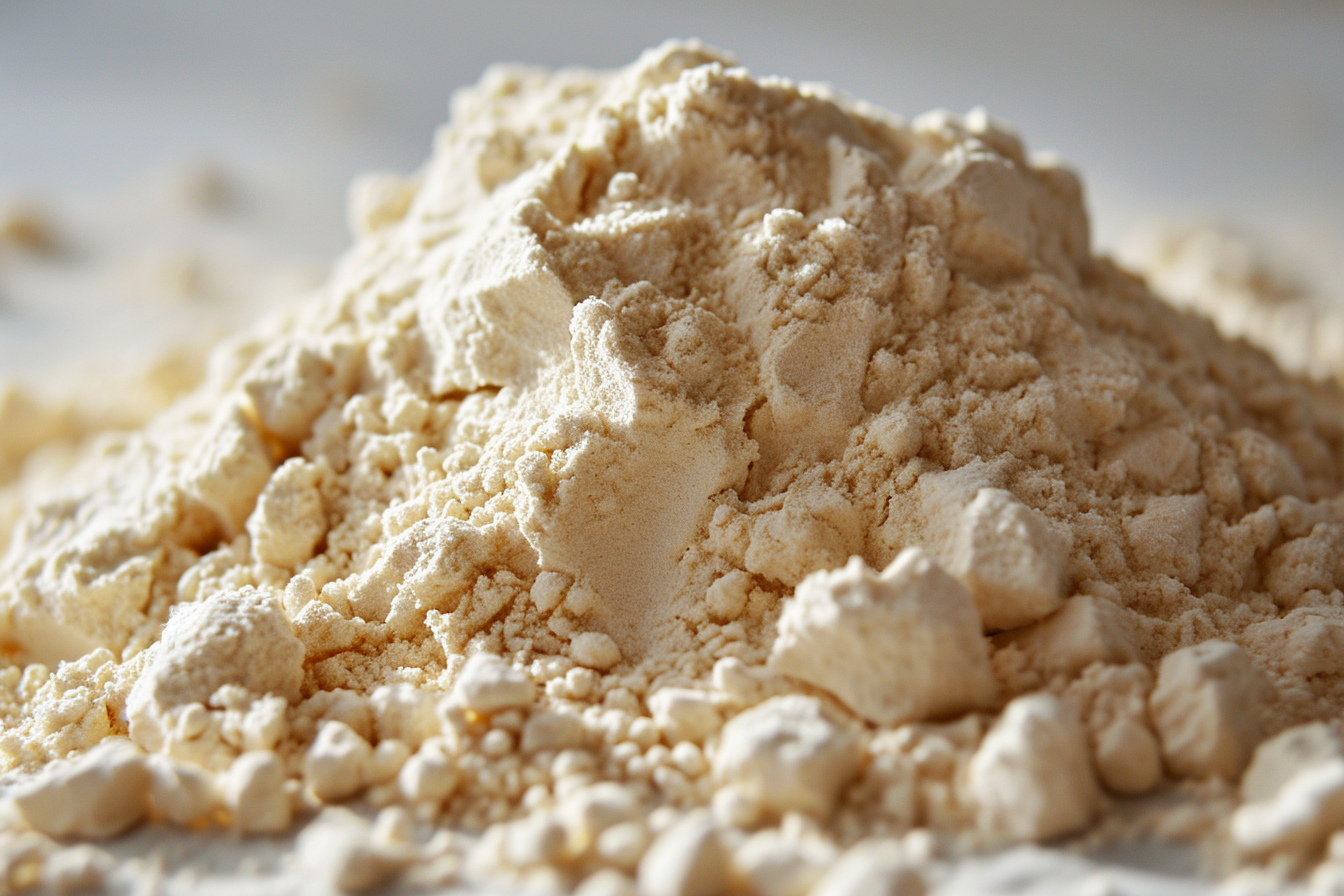

Among the myriad of options available, cerium oxide emerges as a noteworthy contender, renowned for its polishing prowess on glass surfaces. This article delves into the effectiveness, application, and considerations associated with using cerium oxide for phone screen repair.

Cerium oxide, a compound of the rare earth metal cerium, is acclaimed for its abrasive qualities. It's extensively used in the glass and optics industries for polishing and removing minor imperfections from surfaces. When applied to a scratched phone screen, cerium oxide acts by gently grinding down the glass surface around the scratch, effectively diminishing its appearance or, in cases of light scratches, erasing it altogether.

Cerium oxide's reputation as an effective solution for removing scratches from phone screens isn't unfounded. This compound boasts several advantages that make it a preferred choice for both professional restorers and DIY enthusiasts looking to rejuvenate their phone screens. Understanding these benefits can shed light on why cerium oxide is not just a viable option but often a recommended one for minor scratch repair.

Superior Polishing Properties

Cerium oxide's primary advantage lies in its exceptional polishing capabilities. Unlike other abrasive materials that might be too harsh for the delicate glass of phone screens, cerium oxide offers the perfect balance between strength and gentleness. It polishes the glass surface without causing undue stress, making it ideal for smoothing out superficial scratches.

Versatility

Another significant benefit of cerium oxide is its versatility. It's effective on a wide range of glass types, including tempered glass commonly used in smartphone screens. This versatility extends to various types of scratches, from the fine, barely noticeable ones to the more pronounced, though still superficial, marks.

Minimal Risk with Proper Use

When used correctly, cerium oxide poses minimal risk to the phone's screen. Its ability to selectively polish the scratched areas without affecting the surrounding glass makes it a safer alternative to more aggressive methods that might compromise the screen's integrity.

Cost-Effectiveness

For those wary of the high costs associated with professional screen repair, cerium oxide presents a cost-effective solution. With a small amount of the compound and some elbow grease, individuals can potentially restore their screens to near-original condition without the need for expensive replacements or professional services.

DIY-Friendly

The process of using cerium oxide is relatively straightforward, making it accessible to a broad audience. Enthusiasts who prefer a hands-on approach to repair can find numerous guides and tutorials that detail the application process, empowering them to tackle the task with confidence.

The effectiveness of cerium oxide in removing scratches from phone screens can be attributed to its micro-abrasive nature. When applied to a scratch, the compound gently abrades the glass surface surrounding the imperfection. This action gradually levels the glass, making the scratch less noticeable or entirely invisible. Unlike harsher abrasives that might scratch the glass further or create a cloudy appearance, cerium oxide polishes the surface to a smooth finish, restoring clarity and reducing the visual impact of scratches.

Moreover, cerium oxide's chemical composition makes it uniquely suited for this task. It's durable enough to tackle glass surfaces without degrading quickly, ensuring that a small amount goes a long way in the repair process. Its efficacy in polishing and restoring the optical clarity of glass has made it a staple in industries where transparency and finish are paramount, further underscoring its suitability for phone screen repairs.

The application of cerium oxide requires precision and care to avoid exacerbating the issue. The process typically involves creating a slurry by mixing cerium oxide powder with water, and then applying this mixture to the scratched area using a soft cloth or pad. It's crucial to use gentle, circular motions to polish the scratch, ensuring even application without exerting excessive pressure that might lead to further damage.

While cerium oxide is effective, there are several critical considerations to bear in mind:

Cerium oxide offers a promising solution for the removal of light scratches from phone screens, with its effectiveness rooted in its abrasive properties. However, its application demands caution and a nuanced understanding of the limitations inherent to this method. For smartphone users seeking to preserve the longevity and aesthetics of their devices, cerium oxide represents a viable, albeit meticulous, approach to screen repair.

Nonetheless, when faced with deeper scratches or uncertainty regarding the DIY process, consulting with a professional remains the prudent course of action. Through either avenue, restoring the clarity and functionality of a phone screen enhances not only the visual experience but also the overall satisfaction derived from our most trusted digital companions.

Click here to inquire about high-quality cerium oxide polishing powder.

Eric Loewen

Eric Loewen graduated from the University of Illinois studying applied chemistry. His educational background gives him a broad base from which to approach many topics. He has been working with topics about advanced materials for over 5 years at Stanford Materials Corporation (SMC). His main purpose in writing these articles is to provide a free, yet quality resource for readers. He welcomes feedback on typos, errors, or differences in opinion that readers come across.

Inquiry List

Inquiry List