Rare earth elements (REEs) are a group of 17 chemical elements that are essential in many modern technologies, such as smartphones, electric vehicles, and wind turbines. However, these elements are not uniform in terms of their quality or characteristics. The relative purity of materials is a crucial factor that can have a significant impact on their properties and performance. In this article, we will delve into the concept of relative purity in rare earth materials and explore analytical techniques to measure it.

The relative purity of a rare earth material refers to the level of impurities present in the material compared to the ideal or theoretical composition of the material. It is usually expressed as a percentage and indicates the proportion of the rare earth elements in the sample compared to other elements or impurities that may be present. The higher the relative purity of the rare earth material, the better its quality, and the more suitable it is for use in various applications.

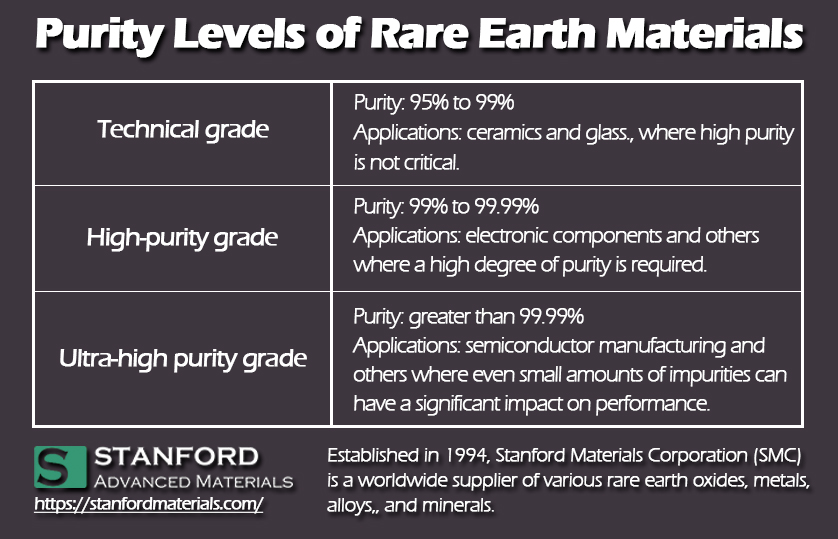

There are several different purity levels used to classify rare earth materials, including:

Technical grade: This is the lowest level of purity, typically ranging from 95% to 99%. Technical grade materials are often used in applications where high purity is not critical, such as ceramics and glass.

High-purity grade: This level of purity typically ranges from 99% to 99.99%. High-purity materials are used in applications where a high degree of purity is required, such as in electronic components.

Ultra-high purity grade: This level of purity is typically greater than 99.99%. Ultra-high purity materials are used in applications where even small amounts of impurities can have a significant impact on performance, such as in semiconductor manufacturing.

There are several analytical techniques available to measure the relative purity of rare earth materials, including inductively coupled plasma mass spectrometry, X-ray fluorescence, and optical emission spectroscopy.

ICP-MS is a powerful analytical technique that can detect and measure trace elements and impurities in a sample. It is highly sensitive and accurate and can detect impurities in rare earth materials at very low concentrations. However, this method requires a complex and expensive instrument and skilled operators to perform the analysis.

XRF spectroscopy is a non-destructive analytical technique that can measure the elemental composition of a material. It is often used to determine the relative purity of rare earth materials, as it can quickly identify impurities and determine their concentration. This technique is relatively simple, fast, and inexpensive compared to other methods.

OES is a technique that uses the emission of light from a sample to determine its elemental composition. It is commonly used to measure the relative purity of rare earth materials, as it can identify and quantify impurities present in the sample. This technique is relatively simple and fast but may not be as sensitive as other methods.

In conclusion, the relative purity of rare earth materials is a crucial factor that can impact their functionality and performance in modern technologies. Several analytical techniques, such as XRF spectroscopy, ICP-MS, and OES, are available to measure the relative purity of these materials. By understanding the concept of relative purity and utilizing appropriate analytical techniques, researchers and engineers can ensure that rare earth materials are of high quality and suitable for use in various applications.

For more information about rare earth materials, please visit our homepage.

Eric Loewen

Eric Loewen graduated from the University of Illinois studying applied chemistry. His educational background gives him a broad base from which to approach many topics. He has been working with topics about advanced materials for over 5 years at Stanford Materials Corporation (SMC). His main purpose in writing these articles is to provide a free, yet quality resource for readers. He welcomes feedback on typos, errors, or differences in opinion that readers come across.

Inquiry List

Inquiry List