Phosphors are materials that absorb energy and release it as light. This makes them glow in the dark. Phosphors are used in many areas, including lighting, displays, and anti-counterfeiting technology. In this article, we will look at the main types of phosphors and how rare earth elements play a key role in their performance.

Phosphors come in different types based on their composition. The most common types are inorganic phosphors, organic phosphors, and rare earth phosphors.

Inorganic phosphors are made from compounds like zinc sulfide (ZnS) and yttrium oxide (Y2O3). They are known for their stability and long lifespan. These phosphors can glow for a long time after absorbing light. They are often used in LED lighting, displays, and emergency exit signs. Inorganic phosphors are reliable and can last for many years, making them a popular choice in industrial applications.

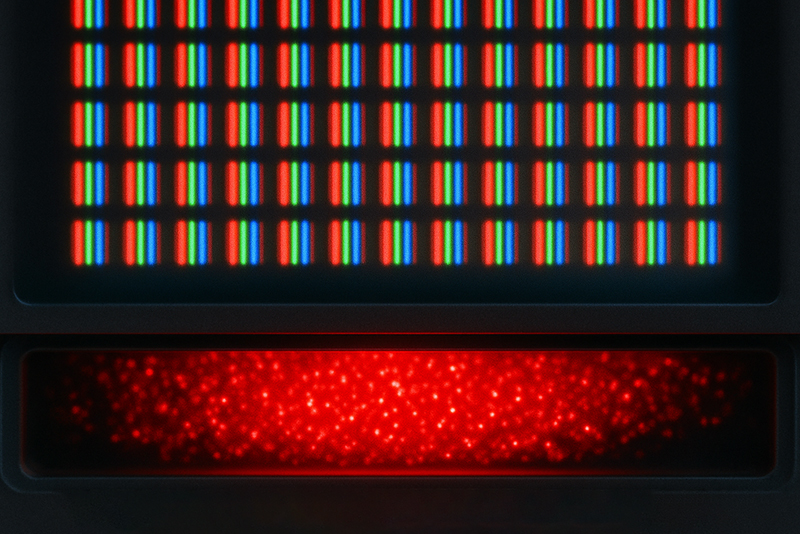

Organic phosphors are different because they are based on organic compounds. They are not as durable as inorganic phosphors and usually have shorter lifespans. However, they are flexible and can be used in thin and flexible displays like OLEDs (Organic Light-Emitting Diodes). OLED displays are becoming more common in smartphones and televisions because of their bright colors and thin design. Despite their shorter lifespan, organic phosphors are important in the development of new display technologies.

Rare earth phosphors are unique because they use elements from the rare earth group. These elements include europium (Eu), cerium (Ce), and gadolinium (Gd). Rare earth phosphors are highly efficient and have long-lasting glow effects. They can emit different colors depending on the type of rare earth element used. For example, europium emits a bright red light, while cerium emits blue. Rare earth phosphors are commonly used in LED lights, displays, and anti-counterfeiting inks. Their ability to emit bright, long-lasting light makes them ideal for high-performance applications.

Further Reading: The Role of Lanthanides in Colored Phosphors

Rare earth elements are essential in creating high-quality phosphors. These elements have special properties that allow them to efficiently convert energy into light. This makes them important in applications where high performance is needed.

Rare earth elements have a special electronic structure. This allows them to absorb energy and re-emit it as light in a controlled way. They also provide stability, which helps phosphors last longer. Some of the most important rare earth elements in phosphor technology include:

Rare earth phosphors offer several advantages over other types of phosphors. They can efficiently convert absorbed light into visible light, making them very effective. These materials also provide a long-lasting glow, which is why they are used in emergency lighting and glow-in-the-dark products. The color of the light can also be adjusted by changing the rare earth elements used. This flexibility allows for precise control over the color output, which is important in displays and lighting systems.

Phosphors are essential in many modern technologies, from lighting to displays and security systems. Inorganic, organic, and rare earth phosphors each offer unique benefits, but rare earth phosphors are especially valuable for their efficiency, durability, and ability to produce vivid colors. Rare earth elements like europium and cerium are critical in ensuring high performance in these applications. Stanford Materials Corporation (SMC) is at the forefront of providing high-quality rare earth phosphors and materials to meet the growing demand for these advanced technologies. As the industry evolves, SMC will continue to support innovation with its expertise and reliable supply of essential materials.

Rare earth phosphors are also stable and durable, which makes them suitable for long-term use. For example, LED lights that use rare earth phosphors can last for many years, reducing the need for frequent replacements.

Eric Loewen

Eric Loewen graduated from the University of Illinois studying applied chemistry. His educational background gives him a broad base from which to approach many topics. He has been working with topics about advanced materials for over 5 years at Stanford Materials Corporation (SMC). His main purpose in writing these articles is to provide a free, yet quality resource for readers. He welcomes feedback on typos, errors, or differences in opinion that readers come across.

Inquiry List

Inquiry List