Magnesium is a light-weighted metal with numerous favorable features. However, this active metal lacks corrosion resistance and ductility. To overcome these limitations, magnesium is usually mixed with aluminum, silicon, copper, and rare earth elements to form alloys with a variety of desirable properties.

Magnesium-cerium master alloys come with great creep resistance and ductility at high temperatures. They are composed of magnesium and over 20% cerium, and are extensively employed in automobiles, electronics, and most importantly orthopedics. Stanford Materials Corporation (SMC) provides high-purity magnesium-cerium master alloys for you. Send us an inquiry if you are interested.

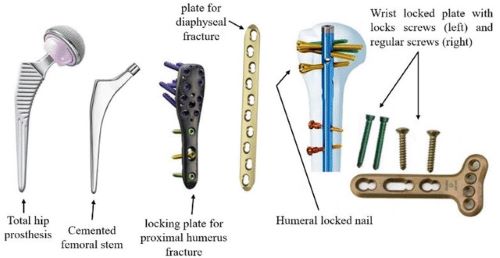

Firstly, magnesium-cerium master alloys have excellent mechanical features, which make them ideal for use in orthopedic applications. These alloys share a high strength-to-weight ratio with magnesium, which means they can provide strong support without adding unnecessary weight or bulk. They are also very ductile, which means they can be easily molded into complex shapes and designs. Thus, magnesium-cerium master alloys are applied to make implants to stand stress and increase mobility.

Secondly, magnesium-cerium master alloys obtain chemical stability with the addition of cerium, which enhances their corrosion resistance, making them an ideal material for orthopedic implants. Since these implants are often subjected to harsh environmental conditions, including bodily fluids and chemicals, magnesium-cerium master alloys are crucial in ensuring that that implants do not corrode and degrade over time. They can maintain their strength and integrity for longer periods and reduce the need for replacement surgeries.

Thirdly, magnesium-cerium master alloys have excellent biocompatibility, which is mandatory for orthopedic implants. A biocompatible material allows living human tissues to interact with implants safely. That is to say, when used in orthopedic implants, they do not cause any adverse reactions or toxicity, and they do not induce inflammation or tissue damage. This makes them perfect for orthopedic parts, such as screws and scaffolds, where they can provide excellent strength and support without harming the patient.

[1]

[1]

Figure 1. Orthopedic Implants

Fourthly, magnesium-cerium master alloys are resorbable materials for bone implants that do not need secondary surgery. Compared with surgical steel, titanium, and other implant materials, such alloys do not require replacement surgery if the implant loosens or get damaged. Instead, they can be gradually absorbed by the body over time. This property is particularly useful for orthopedic implants, as it allows the implant to gradually be replaced by natural bone tissue. The risk of complications will be reduced and the life quality of patients will be improved consequently.

Finally, magnesium-cerium master alloys are cost-effective, making them an attractive option for orthopedic uses. Compared with titanium, cobalt-chromium alloys, and other materials used in orthopedic implants, magnesium-cerium master alloys are relatively inexpensive and widely available. This feature makes them a practical and affordable option for many patients and healthcare providers.

According to the Journal of Magnesium and Alloys, magnesium-cerium master alloys have been proven to have positive effects on the bone healing process for the following reasons.

In a word, magnesium-cerium master alloys have attracted a range of attention in orthopedic sectors for their promising mechanical properties, chemical stability, biocompatibility, degradability, and lower cost. So, they become a popular choice for orthopedic implants. As research continues into the features and benefits of these alloys, we can expect to see them used more widely in the orthopedic industry in the coming years.

Stanford Materials Coporation (SMC) is a leading supplier of magnesium-cerium master alloys. For more information, please check our homepage.

Reference:

[1] Davis, Rahul & Singh, Abhishek & Jackson, Mark & Coelho, Reginaldo & Prakash, Divya & Charalambous, Charalambos & Ahmed, Waqar & Rosa Ribeiro da Silva, Leonardo & Lawrence, Abner. (2022). A comprehensive review on metallic implant biomaterials and their subtractive manufacturing. The International Journal of Advanced Manufacturing Technology. 120. 10.1007/s00170-022-08770-8.

[2] Ning Wang, Shude Yang, Huixin Shi, Yiping Song, Hui Sun, Qiang Wang, Lili Tan, Shu Guo, Magnesium alloys for orthopedic applications: A review on the mechanisms driving bone healing, Journal of Magnesium and Alloys, Volume 10, Issue 12, 2022, Pages 3327-3353, https://www.sciencedirect.com/science/article/pii/S2213956722003012

Eric Loewen

Eric Loewen graduated from the University of Illinois studying applied chemistry. His educational background gives him a broad base from which to approach many topics. He has been working with topics about advanced materials for over 5 years at Stanford Materials Corporation (SMC). His main purpose in writing these articles is to provide a free, yet quality resource for readers. He welcomes feedback on typos, errors, or differences in opinion that readers come across.

Inquiry List

Inquiry List